Efficient, reliable

and lightweight

threaded connections

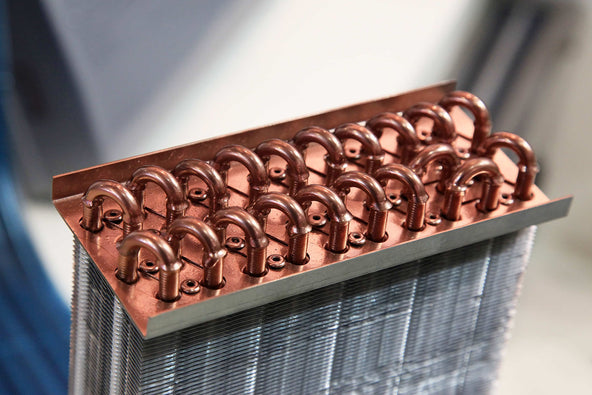

Friction drilling is changing the world to achieve stronger, cheaper, and quicker fastening connections.

Flowdrill Range of tooling

Flowdrill offers a range of tooling designed to meet the specific demands of the desired connection. Our “Flowdrill standard” creates a collar around the hole, made from the base material. This collar adds extra strength and often serves as a sealing. In addition to our collared version, we provide the “Flowdrill Flat” this friction drill removes the collar by cutting the material away, leaving a flush surface finish. When working with aluminum, we have specifically designed the "Aludrill" to prevent aluminum from sticking to the friction drill.

When using Flowdrill as a fastening solution, you can achieve stronger and more reliable connections for your projects.

Request a sample

Nothing beats a hands on sample, allowing you to see what is possible with friction drilling and convince your team of where you may have been missing out or the opportunities it could bring.

Product finder

What kind of Flowdrill friction drill do I need?

This differs on the basis of material, type of solution and size of the drill hole. For every application, we find the suitable friction drill.

Flowdrill enquiries

Flowdrill is trusted by

Top 3 questions: How easy is it to switch from rivet nuts and weld nuts to Flowdrill?

- Does friction drilling work in my material?

Almost all materials that can be bent or deformed without being brittle are suitable for friction drilling. If you have any questions, Flowdrill is eager to help you understand the possibilities. We have extensive experience, drilling mild steel up to 1000mpa and above, stainless steel, and aluminum 6000 grades. Don’t hesitate to get in touch with us as we can check our material database for suitability or conducting supporting tests to identify our limits.

2. Is a Flowdrill connection strong enough

The rule of thumb is that the thicker the material and the higher its tensile strength, the stronger the connection will be. Often, a Flowdrill connection surpasses traditional fastening methods in strength. For instance, with an M6x1.0 in 2mm mild steel, we can achieve a pull-out force of 19.4 kN and a torque of 16Nm—exceeding that of an 8.8 class bolt. Moreover, we conduct in-house durability and strength tests. If you have any questions or concerns regarding the required strengths, please reach out to us.

3. Do I need new machinery?

Friction drilling is feasible on CNC machines, tube laser, and pillar drill. However, we strongly advise against using a hand drill for friction drilling. We offer specialized tool holders tailored for each type of machine. If you would like to determine whether your machine is suitable for friction drilling or are interested in exploring the capabilities of a new machine, please feel free to contact us for more information.