HVAC

HVAC

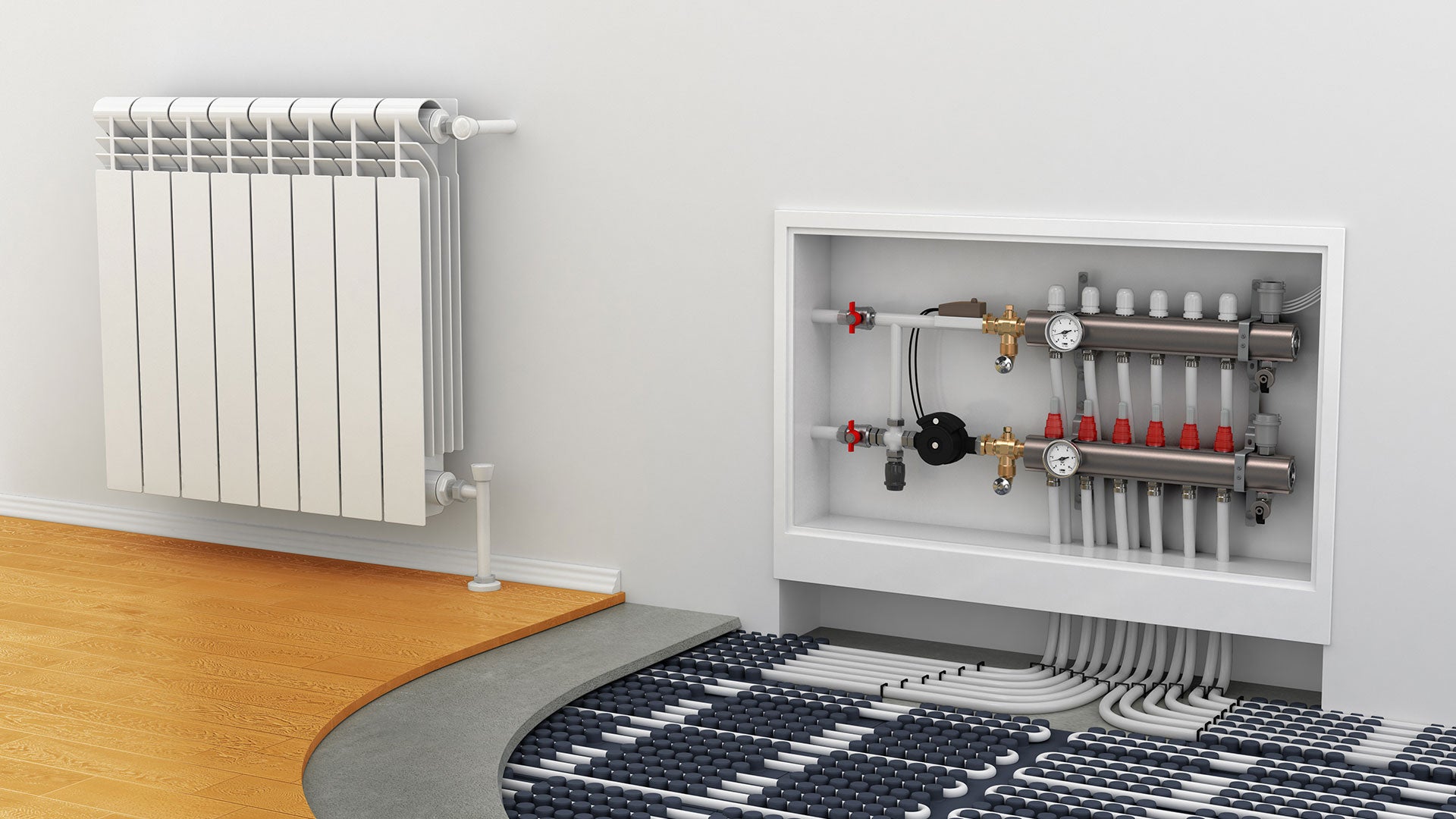

Flowdrill’s ability to Increase material thickness, with friction drilling, in copper and stainless steel is a major plus point for the heating, ventilation and air conditioning sector and allows our customers to reduce leaks, improve soldering and support the use of gas type threads.

Our friction drilling technology, which is used by global specialists Watts, Trane, Flamco and Lennox, is perfect for use in connecting parts in heat exchangers, air conditioning units, boilers and underfloor heating manifolds.

Meeting the highest standards

Our Application Engineers have a proven track record of supporting prototype development and proving out new products, ensuring support from your first idea through to running production.

Flowdrill difference in the HVAC industry

- Reduced material costs

- Elimination of welding bosses and laborious leak testing

- Leak proof connection

- Better brazing connection

Flowdrill is trusted by

Changing the way the world achieves stronger and quicker fastening connections.

Flowdrill is a tungsten carbide friction drill that provides a cost effective and reliable connection alternative to traditional fastening methods such as rivet, insert and weld nuts.