General Fabrication

General Fabrication

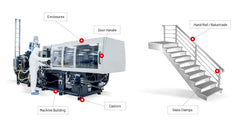

Flowdrill’s versatility means it is a trusted partner with more than thousands of customers in general fabrication, ranging from a world leader in DIY products and a modular building specialist to food processing giants and digital menu boards for McDonalds.

Whilst all have different applications, they all strive for an elimination of reworks, improvements in cycle times and the best possible product appearance.

Quick set-up is also a major benefit we can deliver, with our friction drills we are able to achieve 90% reduction in set-up times, meaning production can begin within a minute.

“One of the really pleasing things about using the friction drill technology is the final aesthetics of our product. The countersink method means there is a completely smooth finish, and no nuts are protruding…clients are no longer commented on the grinding marks, but instead saying ‘wow, how did you do that’.”

-

Matthew Carter, Production and Programming Specialist at StairSupplies